Factory

The factory’s geographical position in the municipality of Balaguer within the region of La Noguera (Lleida) is advantageous on several strategic levels. These include the relationship between cost and production and the ease of reaching our core markets, as we have excellent connections with the north and the interior of the Iberian Peninsula, with the metropolitan area of Barcelona and its port, and we are just a short distance away from the French border, the gateway to Europe.

The space we have available, with an area of over 26,000m², of which 5,500m² is made up of buildings, offers an excellent working base in which to perform our activities.

Administration and Management

The central facility in Balaguer is where our head office is located and where, as a general rule, matters regarding accounting, IT, purchasing control and finance are efficiently handled.

Laboratory

This is a key area for the company, and that is why we make sure we have highly qualified staff who are constantly updated with the latest discoveries in the world of chemistry and paint colour mixing. We also strive to equip our facilities with the necessary machinery to ensure the success of our products.

It is in the laboratory where the technical department (which includes R+D+I, quality control of raw materials and finished products and technical support (SAT) analyses problems, studies solutions and looks to resolve each specific case.

Technology and knowledge come together in this environment which is the spearhead of our company.

Marketing

A job well done is reflected in the quality of the technical data sheets, where detailed information about our products can be found.

Master Safety Data Sheets are an essential tool in the marketing of chemicals today.

We have UNE 48243:2007 certification for many of our paints.

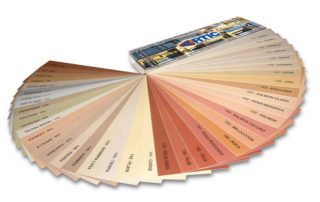

The Artic colour chart is very well-designed tool, based on years of experience and statistics in the world of interior and exterior renovations. Made with real paint (not with lithography) in a large format, the selection of colours on the chart allows you to visualize how contrasting colours play off each other.

Product catalogues.

Pamphlet describing Artic’s leading specialities.

Catalogues describing processes: insulating and restoring façades, waterproofing, flooring, industrial maintenance, decoration, etc.

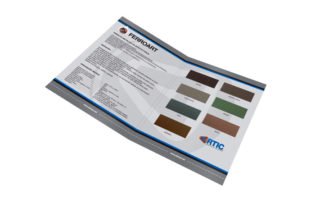

Physical samples of different processes.

Purifier

This is the last stage on the circuit of each manufacturing process described above.

The result is a factory that fully respects the environment and sustainability and complies with all the standards that relate to them.

Dispatching

The warehouse of finished products has a large stock capacity and is fully computerized for efficient stock management. This ensures that our processes are fast and dynamic as well as keeping us close to our clients.

Production

The entry of raw materials is handled automatically without manual handling of the resins and aggregates that will later be used in the production of paints and coatings.

The material arrives by tanker trucks and passes through a series of ducts to the silos, where it is stored. The other raw materials, packaging, etc. are stored in the warehouse, strategically placed alongside the production lines.

The production capacity is separated by the type of products to be manufactured and their respective quantities.

This is a computerized system of production, packaging, palletizing and wrapping of water-based products.

From the control centre, instructions are given to prepare the relevant material.

Once given the green light, the button is pressed to start the operation. From the silos the raw materials are sent to the tanks, where the paint is produced by dispersion.

Having passed through quality control, the process continues automatically: it is stored, palletized, packed and placed in the warehouse for finished goods and shipments.

The result is a production capacity, on this line only, of about 120 tonnes per day.

Because of our wide product range, there are some lines with added value which deserve special attention and are produced in tanks of 200 to 1,500 litres using a less automated format but still guaranteeing the outstanding quality we are known for.

Dispersers with variable speeds, mills with high-tech filtering, everything necessary to achieve high quality in terms of refinement and gloss, not forgetting the distinctive qualities of each individual product.

A specialized production unit for powder-based mortars using very specific materials, specially designed for the restoration of façades and paved floors, which results in highly customized products with high added value.

All tar and resin production involves certain special characteristics that require us to work with specific reactors separately from the other production lines.